焦點新聞

重要建築物之結構分析及保護方案

澳門世界遺產歷史建築物

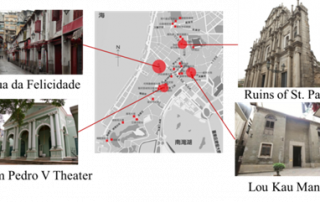

澳門在2003年後隨著博彩業的開放,各項大型酒店及相關建設得到快速的發展。在另一方面,聯合國教科文組織亦於2005年宣布了澳門舊城區成功被列入為世界遺產名錄中。而應對風災對重要建築物的影響是其中一項重點工作。本澳現有重要的結構建築物大致可以分為三大類型:(一 […]

鋼構材成形過程(冷成形、三維打印技術)對鋼結構性能的影響

Cold-formed metal structures

No longer a Dream for predicting geometric imperfection, residual stresses and strength enhancement in cold-formed steel structures realistically! […]

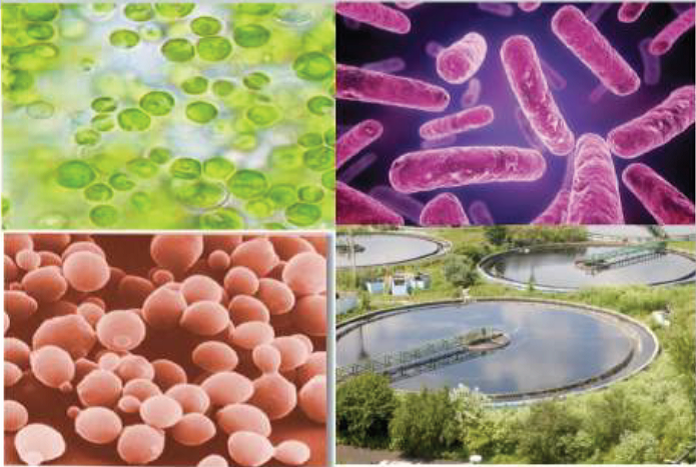

新的觀點:利用微生物清理受污染的環境

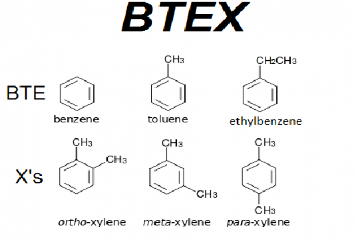

Combined (Bio)Remediation of Environment Contaminated with Mixed Wastes (BTEX/CAHs/MTBE)

| […] |

視像簽約!澳大與中科院海洋研究所成立海洋環境與工程聯合實驗室

澳門大學今(24)日舉行“澳門大學—中國科學院海洋研究所合作框架協議簽署儀式”,成立海洋環境與工程聯合實驗室。雙方將充分發揮在海洋環境與生態、海洋工程等領域的研究優勢,促進彼此在相關科學領域的研究與發展,為澳門及粵港澳大灣區的科技創新帶來裨益。是次簽署通過視像進行,是澳大歷史上首次以視像會議的形式舉行簽約儀式,此舉充分體現了澳大在科技交流合作在任何時 […]

澳門大學參與南方海洋科學與工程廣東省實驗室(珠海) 第二批合作共建單位簽約儀式

12月03日,南方海洋科學與工程廣東省實驗室(珠海)舉行第二批合作共建單位簽約儀式。第二批合作共建單位包括香港、澳門、廣東等地高校,以及國家海洋環境預報中心和相關企事業單位等14家。廣東省基礎與應用基礎研究基金委主任曾路、珠海市副市長閻武、中山大學常務副校長孫冬柏出席會議並致辭。主持人中國科學院院士、南方海洋實驗室主任陳大可介紹南方海洋實驗室基本情況,實 […]

澳門海事及水務局代表團參訪澳門大學

11月5日,澳門海事及水務局副局長郭虔率代表團參訪澳門大學,獲澳門大學校長宋永華校長熱情接待。出席參訪活動的澳門海事及水務局代表包括海域管理廳廳長林純、海洋技術處處長黃昆侖及海域管理廳高級技術員鄭漢樺。

出席活動的澳門大學代表包括,澳門大學科技學院院長須成忠、土木與環境工程系主任兼區域 […]

活動預告

重要建築物之結構分析及保護方案

澳門世界遺產歷史建築物

澳門在2003年後隨著博彩業的開放,各項大型酒店及相關建設得到快速的發展。在另一方面,聯合國教科文組織亦於2005年宣布了澳門舊城區成功被列入為世界遺產名錄中。而應對風災對重要建築物的影響是其中一項重點工作。本澳現有重要的結構建築物大致可以分為三大類型:(一)以磚木或石材建成的古建築物丶(二)鋼筋混凝土建築物及(三)鋼及金屬建築物。對於用不同材料建造的建築物,其相關抗風處理亦會有所不同。因此本澳有必要完善對相關重要建築物在抗風方面的能力及保護加固方面作更多的研究,以規模業界在相關工作之標準。

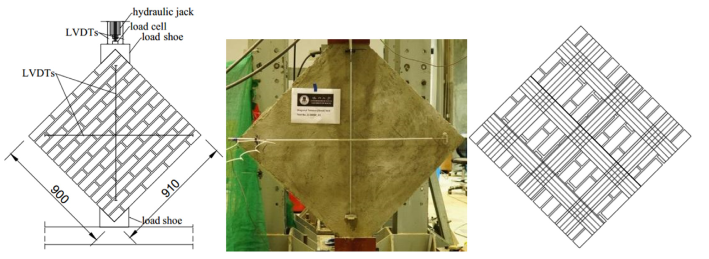

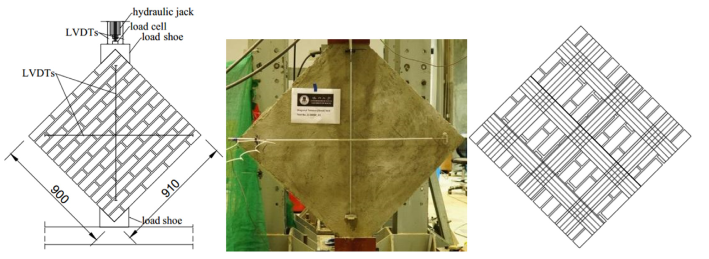

砌體結構是澳門及世界上最常見的一種建築結構,但對於砌體結構建築特性的系統性科學研究還較少。本項目針對現有建築修復與保護的需要,特別是對於有價值的古代砌體結構建築,同時結合節能環保,經濟效率,和文化價值等多方面考慮,探索新型複合材料的創新加固技術在土木工程領域的應用研究。纖維增强無機基質新型複合材料(在文獻中作爲TRM,FRCM等的統稱)因其良好的兼容性與耐久性最近受到了土木工程學界很大的關注。研究針對不同的纖維增强無機基質的新型複合材料的特性和加固效果,運用國際先進的實驗和數值模擬技術,探索新型複合材料的創新加固技術替代傳統古代建築修復和保護技術的潜力,提高建築保護修復的安全性和可靠性,降低建築修復的風險和工作量。[1-3]

纖维材料加強之砌體實驗試件

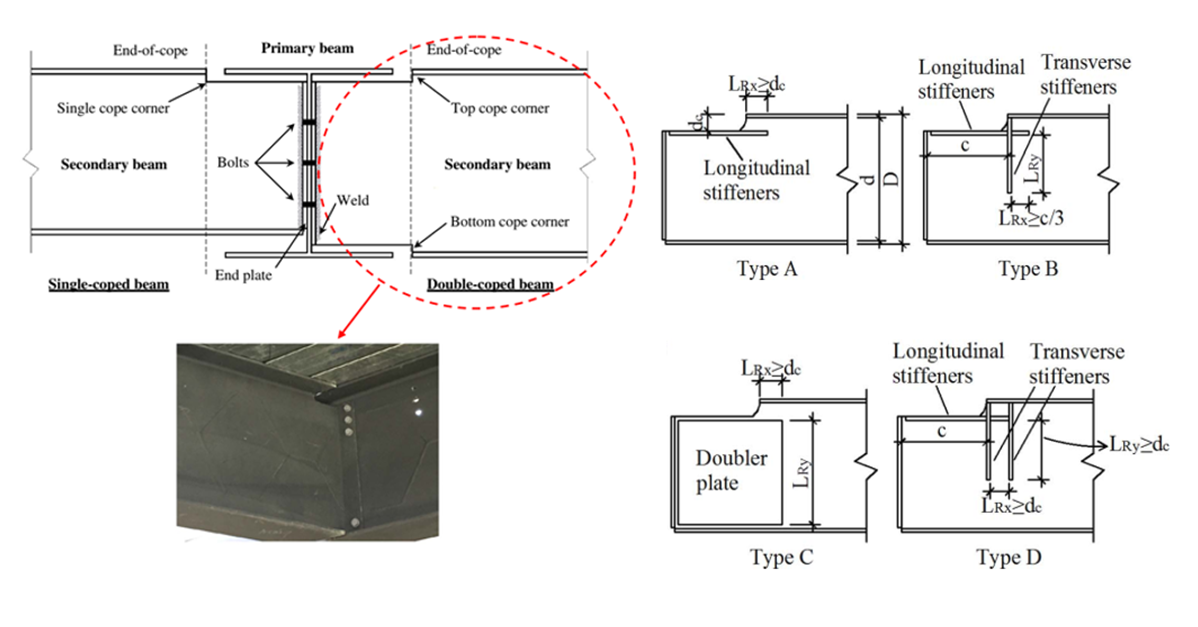

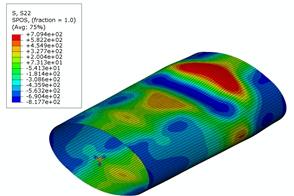

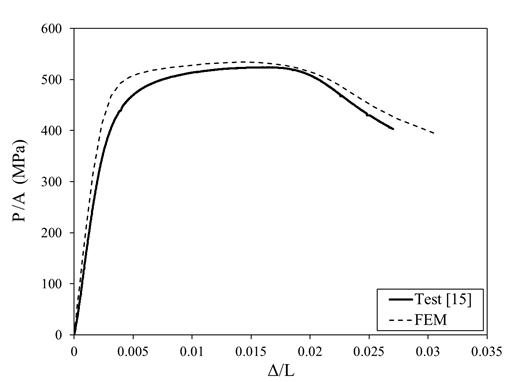

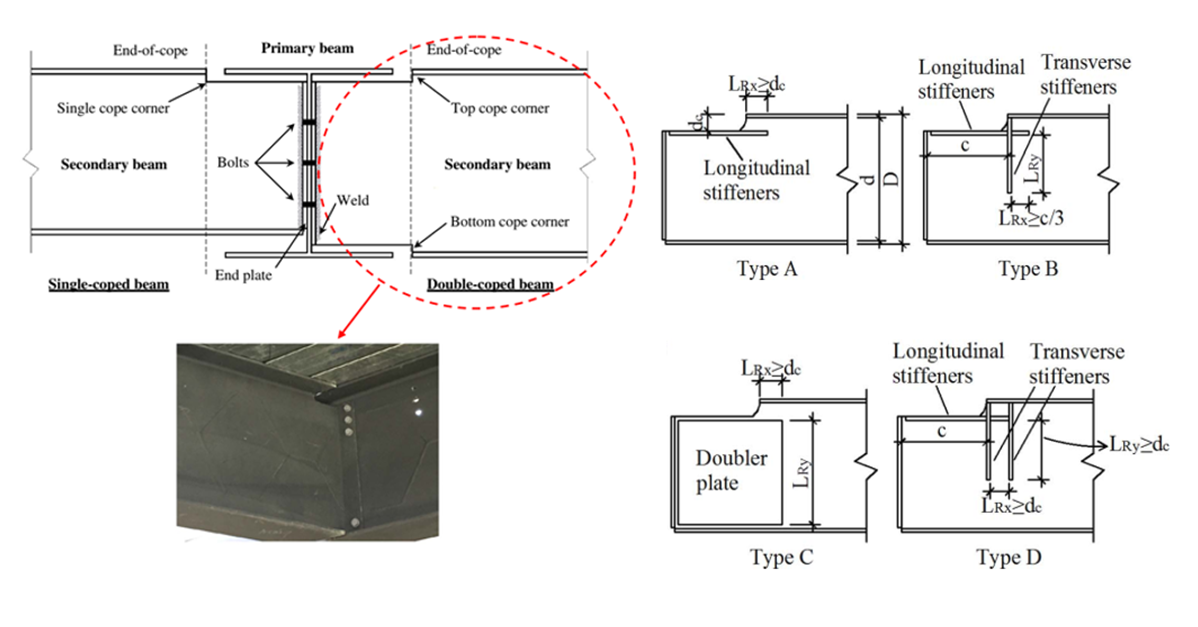

為了應對氣候變化所產生的各種自然荷載(例如颱風、温度變化等自然現象)對建築物的影響,新型材料及高強度材料在建築上之應用需求有著上升的趨勢。高強度鋼材由於其優勝之強度重量比特性,其應用在鋼結構設計中的比例日益提升。由於其高強度的特性,在設計某些受壓構件時,其承載能力往往會受制於其細長比系數。為更有效地提升其承載能力,在此情況下可以加入適當設計之加勁板。由於現有對鋼結構加勁板之設計公式大多數是基於以往低至中等強度的鋼材所得到的,有關於設計高強度鋼材加勁板的公式 相对比較少。因此有必要對高強度鋼材設計進行更多之實驗及分析研究,進一步提出適用於業界之設計方法及公式,提升設計效率和安全。[4] 對於現存的重要鋼結構建築物而言,高强纖維材料之應用不但能有效地降低裂紋之生長,並且能夠提高現有構件之強度。[5]

鋼結構不同類型之加勁板設計

相關文章

- Wang, X., Lam, C.C., Iu, V.P. (2019). Comparison of different types of TRM composites for strengthening masonry panels, Construction and Building Materials, 219, pp. 184-194

- Wang, X., Lam, C.C., Iu, V.P. (2018). Experimental investigation of in-plane shear behaviour of grey clay brick masonry panels strengthened with SRG. Engineering Structures, 162, 84-96

- Wang, X, Ghiassi, B, Oliveira, D. V., Lam, C.C. (2017). Modelling the nonlinear behaviour of masonry walls strengthened with textile reinforced mortars. Engineering Structures, 134. pp. 11-24

- Lam, C. C., Yam, M.C.H., Fang, C. (2017). Strength and behavior of reinforced double-coped beams against local web buckling. Journal of Constructional Steel Research, 138. pp. 38-50

- Lam, A.C.C., Yam, M.C.H., Cheng, J.J.R. and Kennedy, G.D., (2010) Study of stress intensity factor of a crack steel plate with a single-side CFRP composite patching, Journal of Composites for Construction, ASCE, Vol. 14(6), pp. 791-803

鋼構材成形過程(冷成形、三維打印技術)對鋼結構性能的影響

Cold-formed metal structures

No longer a Dream for predicting geometric imperfection, residual stresses and strength enhancement in cold-formed steel structures realistically! A deterministic approach with advanced numerical modeling of manufacturing processes is a solution.

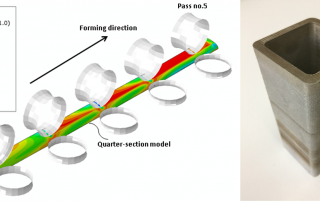

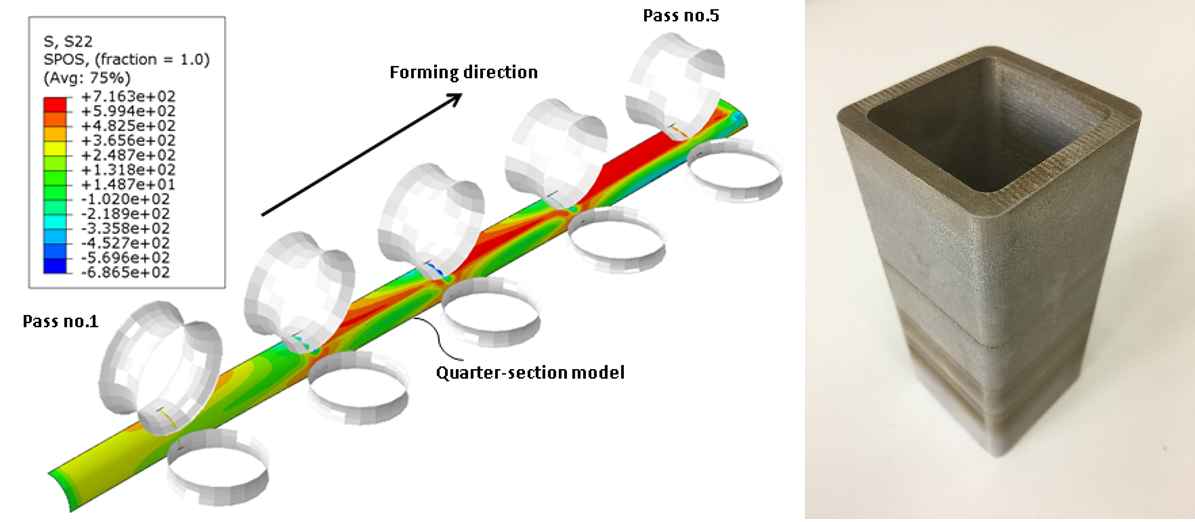

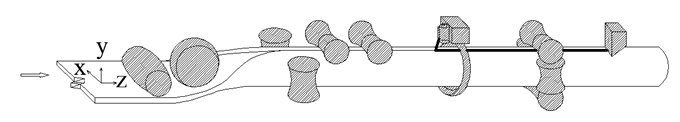

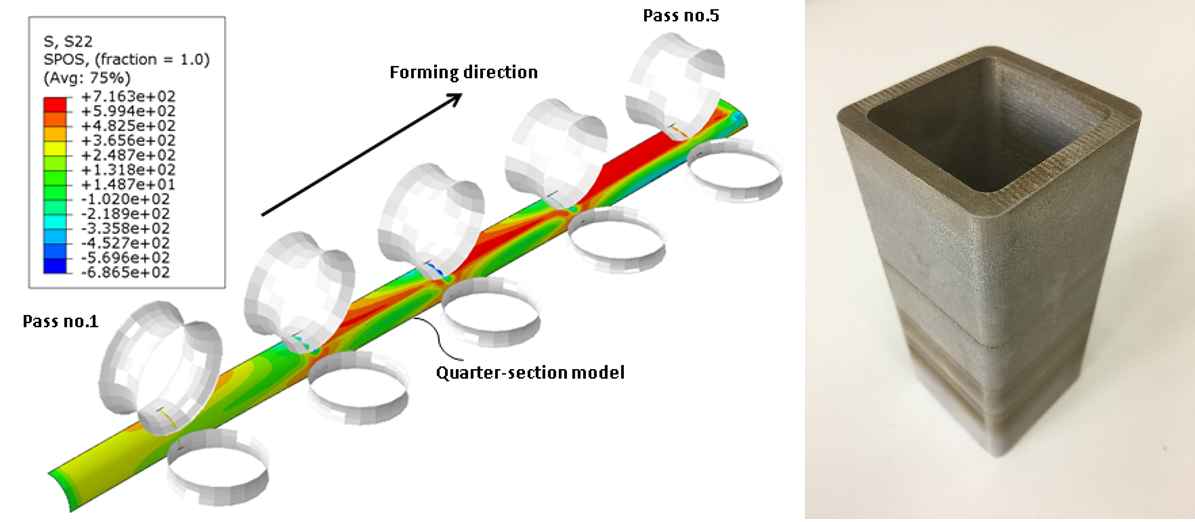

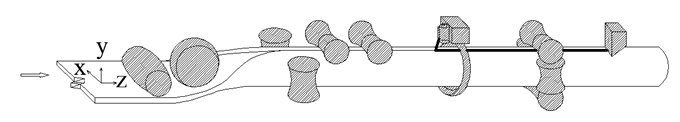

Million tons of cold-formed metal building products are used in construction industry around the world each year. This trend is kept increasing due to their construction efficiency in Modular integrated Construction (MiC). The structural performance of cold-formed thin-walled metal structures is known to be sensitive to initial imperfections which include both geometrical imperfection and cold work due to forming. Traditionally, this cold work effect has been taken into account by using separate specifications of mechanical properties for the flat portions and the corner regions in conjunction with idealized residual stresses models which are based on inappropriate assumptions disregarding the effect of the manufacturing process. Indeed, various cold-formed sections are fabricated by different manufacturing processes (Figs. 1 & 2). Hence, a research has been being carried out to seek for the solution to overcome this shortcoming.

|

| Fig 1. Manufacturing process of roll-formed tubes |

Coiling Uncoiling & Flattening Press Braking |

| Fig 2. Manufacturing process of press-braked sections |

Dr. Quach’s research has been focused on the development of various scientific tools (i.e. analytical models, empirical models, and hybrid analytical-finite element approaches) to accurately model manufacturing processes and quantify initial imperfections and the cold work effect (i.e., residual stresses and plastic strains) and in various types of cold-formed members (e.g. channels and hollow sections). The main contribution from this research is to correct the major deficiencies in existing knowledge and existing design approaches by using these proposed tools. The findings confirm the effect of the manufacturing process on the mechanical and structural performance of cold-formed metal members. The proposed methods/tools can be used to predict geometric imperfections, residual stresses and strength enhancement in cold-formed metal structures realistically.

An integration of these proposed scientific tools forms a novel and unified approach for the analysis and design of cold-formed thin-walled structures. This new approach can be used for optimizing the forming parameters of cold-formed steel sections and will greatly reduce the need for laboratory testing in the development of design rules.

The aforementioned research is a large study involving various parts of research, and is conducted through various projects funded by the university and the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of Macao S.A.R. This research is being developed at three main directions:

(a) Stress-strain models of thin sheet metals;

(b) Simulations and Predictions for enhanced strengths of cold-worked materials;

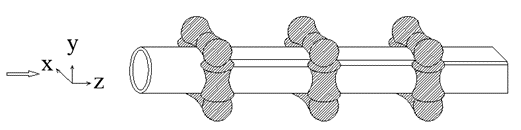

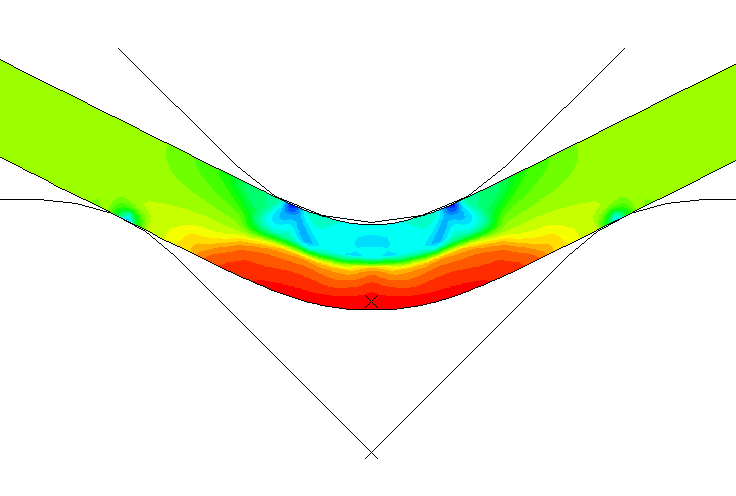

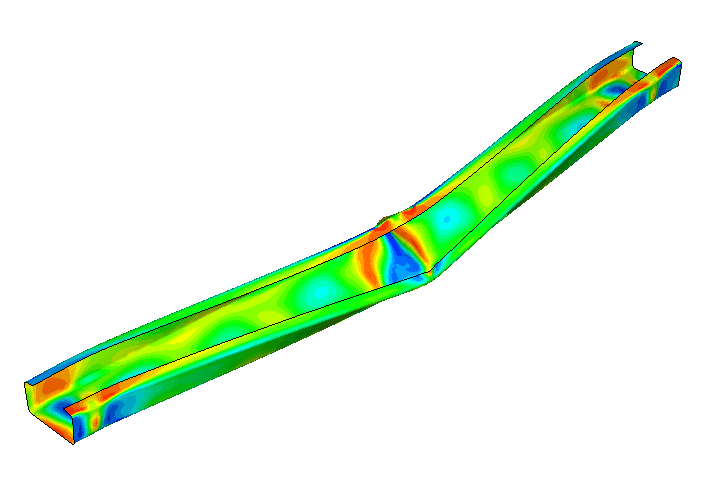

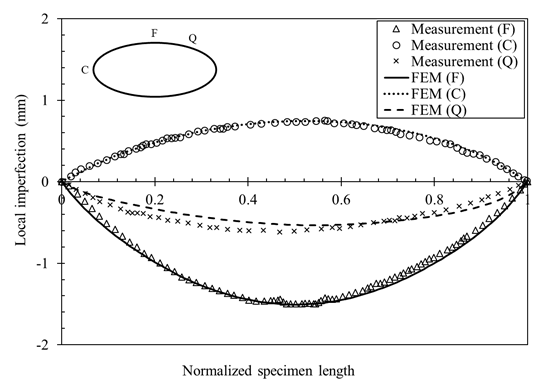

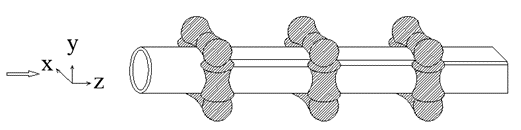

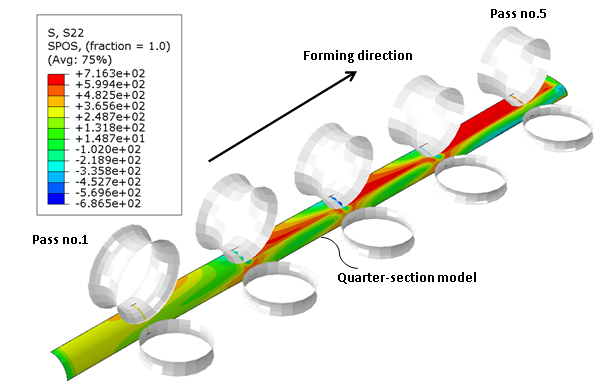

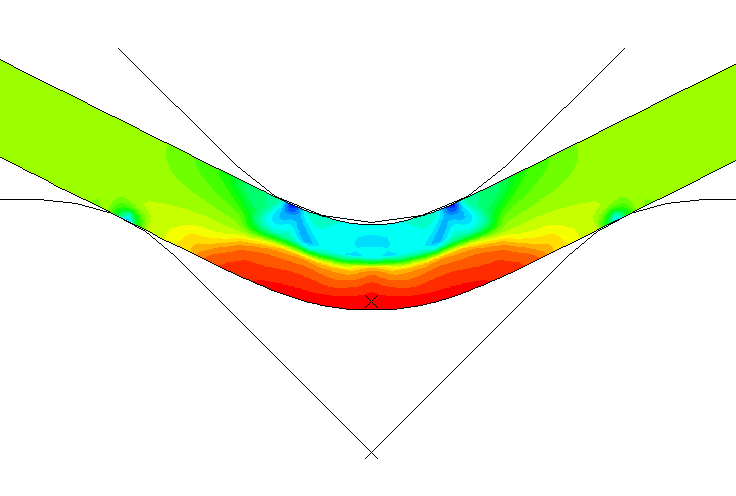

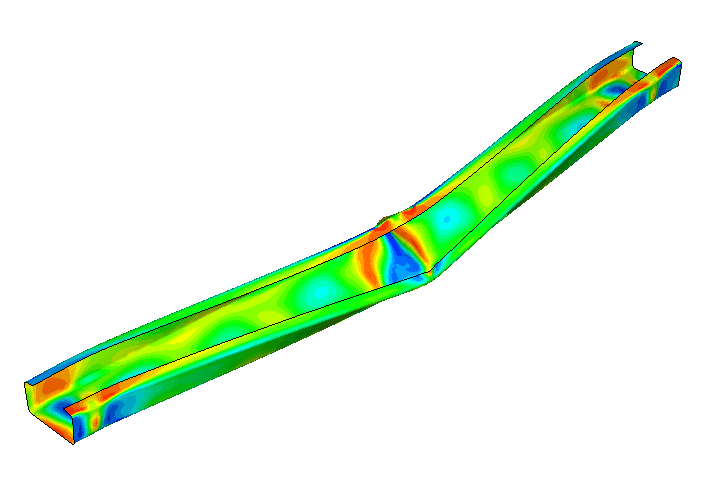

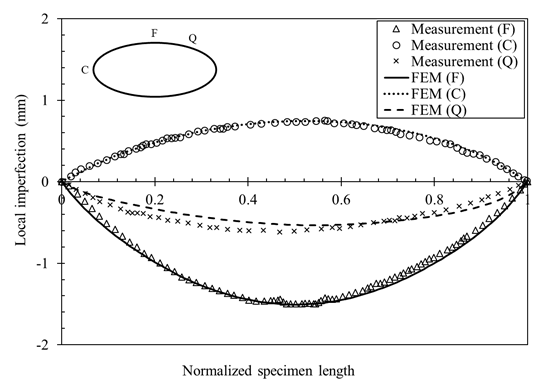

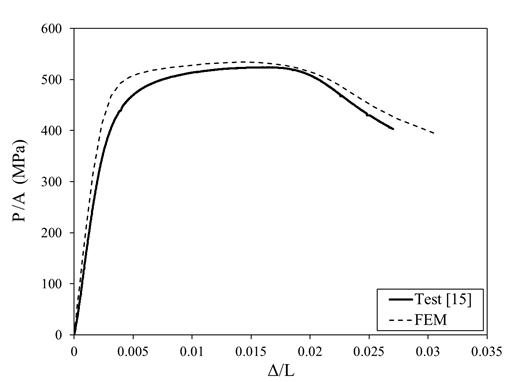

(c) Simulations and Predictions for initial imperfections (including geometrical imperfections, residual stresses, plastic strains) in cold-formed members and their effect on structural performance (Figs. 3~8).

|

|

| Fig 3. Finite element-based method: Numerical tube forming of EHS tubes |

Fig 4. Advanced finite element approach: Numerical stub column test of EHS |

|

|

| Fig 5. Finite element-based method: Numerical press braking |

Fig 6. Advanced finite element approach: Nonlinear buckling analysis |

|

|

| Fig 7. Numerically predicted local imperfections in an EHS | Fig 8. FE predicted stub-column behavior of an EHS |

3D printed metal structural members

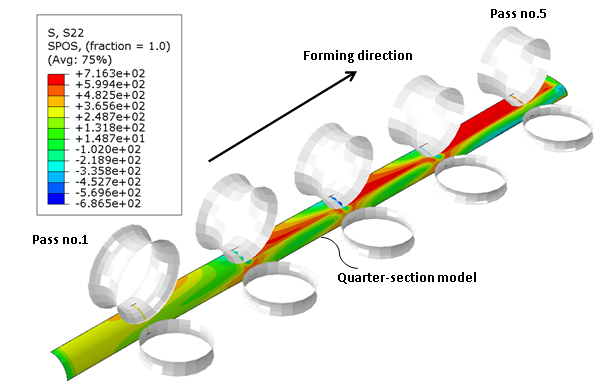

Additive manufacturing, commonly known as 3D printing, is an evolutional technology in the manufacturing industry. This technology has already been embraced by different industries, such as aerospace and biomedical engineering, and the recent advance in this technology has generated a vast of societal excitement for its future. Despite the exciting prospect of its application in civil engineering, additive manufacturing technology is still at a perceived stage for construction industry. The benefits and potential in construction industry are rarely known in the field at this stage. This research aims to investigate the mechanical properties and structural performance of additively manufactured metal tubular sections (see Figs. 9 and 10). So far, high strength steel tubular stub columns additively manufactured by selective laser melting (SLM) with three different scanning patterns, have been tested. The anisotropy on mechanical properties has been examined through tensile coupon tests in both longitudinal and transverse directions. The influences of scanning patterns on mechanical properties and structural behavior of as-printed high strength steel tubular sections stub columns were also investigated. The test results have been used to assess the applicability of existing design provisions that originally developed for conventionally produced hot-rolled and cold-formed steel tubular sections to the additively manufactured high strength steel tubular sections.

|

|

| Fig 9. 3D printing of metals | Fig 10. 3D printed stainless steel tubes |

REFERENCES

(** Research students or Post-Doc from University of Macau. ^Corresponding author)

- Yan, J.J.**, Song, H., Dong, Y.P., Quach^, W.M. , and Yan^, M. (2020), High strength (~2000 MPa) or highly ductile (~11%) additively manufactured H13 by tempering at different conditions, Materials Science and Engineering A, 773, 138845. [Q1 in “Materials science, Multidisciplinary”. Q1 in “Metallurgy & metallurgical eng.”]

- Yao, Y.**, Quach^, W.M., and Young, B. (2019), Cross-section behavior of cold-formed steel elliptical hollow sections – a numerical study, Engineering Structures, 201, 109797. [Q1 in Civil Eng.]

- Cai, Y., Quach^, W.M., and Young, B. (2019), Experimental and numerical investigation of concrete-filled hot-finished and cold-formed steel elliptical tubular stub columns, Thin-Walled Structures, 145, 106437. [Q1 in Civil Eng.]

- Yao, Y.**, Quach^, W.M., and Young, B. (2019), Finite element-based method for residual stresses in cold-formed steel hollow sections, Engineering Structures, 188, 24-42. [Q1 in Civil Eng.]

- Yan, J.J.**, Chen^, M.T.**, Quach, W.M., Yan, M., and Young, B. (2019), Mechanical properties and cross-sectional behavior of additive manufactured high strength steel tubular sections, Thin-Walled Structures, 144, 106158. [Q1 in Civil Eng.]

- Cai, Y., Quach^, W.M., Chen, M.T., and Young, B. (2019), Behavior and design of cold-formed and hot-finished steel elliptical tubular stub columns, Journal of Constructional Steel Research, 156, 252-265. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Yan, J.J.**, Zhou, Y.H., Gu, R.N., Zhang, X.M., Quach^, W.M. , and Yan^, M. (2019), A comprehensive study of steel powders (316L, H13, P20 and 18Ni300) for their selective laser melting additive manufacturing, Metals, 9(86), pp.1-20. [Q1 in Metallurgy & Metallurgical Eng.]

- Abambres^, M., and Quach, W.M. (2016), Residual Stresses in Steel Members: A Review of Available Analytical Expressions, International Journal of Structural Integrity, 7(1), pp.70-94. [Q3 in Civil & Structural Eng. Q3 in Mechanical Eng., according to SJR.]

- Quach, M., and Young^, B. (2015), Material properties of cold-formed and hot-finished elliptical hollow sections, Advances in Structural Engineering, 18(7), pp.1101-1114. [Q2 in Civil & Structural Eng. Q2 in Building & Construction, according to SJR.]

- Quach^, M., and Huang**, J.F. (2014), Two-stage stress-strain models for light-gauge steels, Advances in Structural Engineering, 17(7), pp.937-949. [Q2 in Civil & Structural Eng. Q2 in Building & Construction, according to SJR.]

- Quach^, M., and Qiu**, P. (2014), Strength and ductility of corner materials in cold-formed stainless steel sections, Thin-Walled Structures, 83, pp.28-42. [Q1 in Civil Eng.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2010), Effect of the manufacturing process on the behaviour of press-braked thin-walled steel columns, Engineering Structures, 32, pp.3501-3515. [Q1 in Civil Eng.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2009), Residual stresses in press-braked stainless steel sections – I: Coiling and uncoiling of sheets, Journal of Constructional Steel Research, 65, pp.1803-1815. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2009), Residual stresses in press-braked stainless steel sections – II: Press-braking operations, Journal of Constructional Steel Research, 65, pp.1816-1826. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Quach^, W. M., and Qiu, P. (2009), Accurate prediction of mechanical properties for cold-formed stainless steel section, Journal of Yantai University, Natural Science and Engineering Edition, 22(3), pp.217-228.

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2008), Three-stage full-range stress-strain model for stainless steels, Journal of Structural Engineering, ASCE, 134(9), pp.1518-1527. [Q1 in Civil & Structural Eng. Q1 in Building & Construction, according to SJR.]

- Quach^, W. M., Teng, J. G., and Chung, K. F. (2007), Finite element predictions of residual stresses in cold-formed steel sections, Progress in Steel Building Structures, 9(3), pp.26-32.

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2006), Finite element predictions of residual stresses in press-braked thin-walled steel sections, Engineering Structures, 28, pp.1609-1619. [Q1 in Civil Eng.]

新的觀點:利用微生物清理受污染的環境

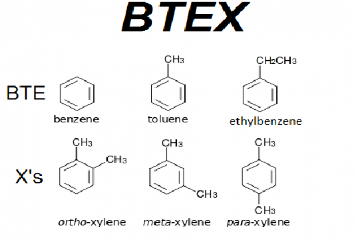

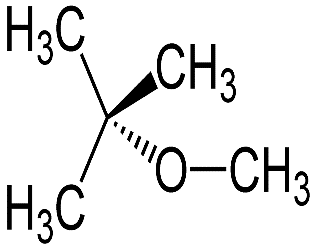

Combined (Bio)Remediation of Environment Contaminated with Mixed Wastes (BTEX/CAHs/MTBE)

|

|

|

| TCE | BTEX | MTBE |

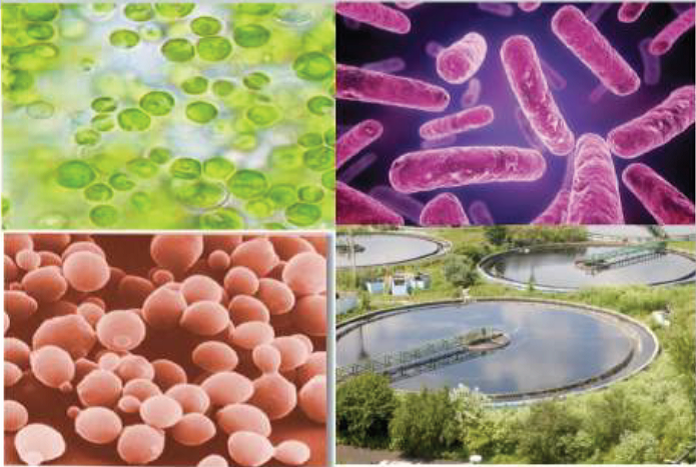

Chlorinated aliphatic hydrocarbons (e.g., TCE), monoaromatic hydrocarbons (e.g., BTEX), and MTBE are major soil and water pollutants as a result of their widespread anthropogenic use. Soil contamination is of particular concern as it results in offsite contamination of groundwater and surface waters by migration of contaminants through and with soil materials. Co-contamination of soil with the mixed pollutants allows for the application of bioremediation to achieve their simultaneous mineralization.

Achievements:

- Isolating indigenous microorganisms capable of degrading BTEX / CAHs / MTBE mixture.

- Construction of effective microbial consortium.

- Establishing optimal process parameters for mixture degradation through laboratory-scale batch/reactor experiments.

- Enhanced removal through microbial immobilization on waste material (e.g., scrap tire, silica gel).

- Determining how interaction (stimulatory or inhibitory) affects DCE and/or TCE co-metabolism and co-metabolizing microbial community structure in the presence of MTBE.

- Identifying microorganisms responsible for MTBE/chloroethenes co-metabolism using culture and biomolecular methods.

- Developing integrated remediation technology that can meet the regional regulation/standards to be set and strengthened in the near future.

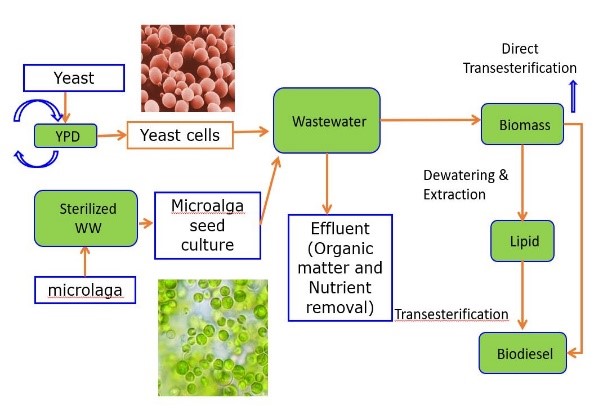

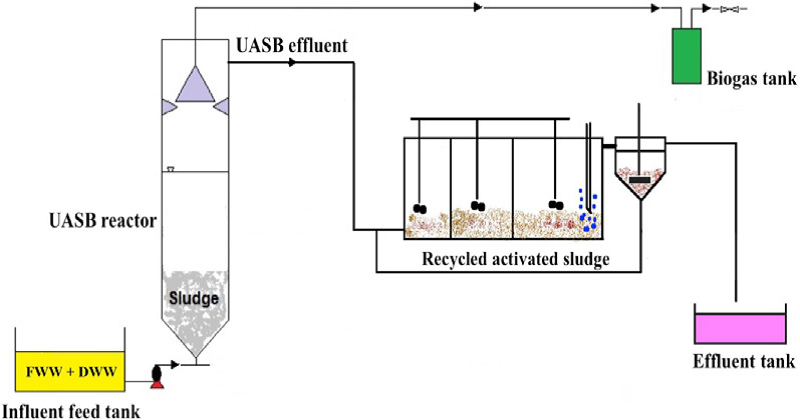

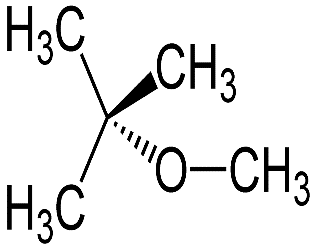

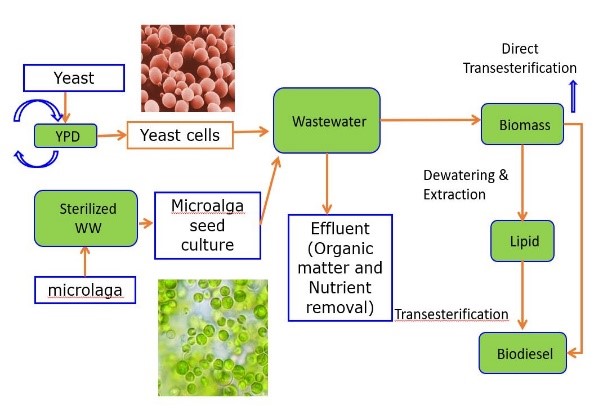

Microbial Biodiesel(/Biogas) Production Simultaneously with Enhanced Wastewater Treatment (and from Food Waste)

|

|

| Biodiesel Production | Biogas Production |

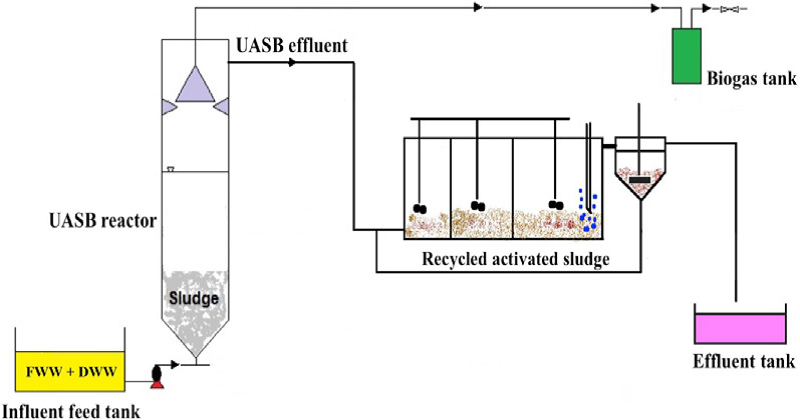

For the purpose of environmentally sustainable development, the recovery of resource or energy from wastes has attracted worldwide attention these days. The wastewater generated from food industries is more difficult to treat than the domestic wastewater due to their high organic loads. For the microbial biodiesel production, the possibility of developing a pre-treatment process which could produce microbial lipid that could be converted to biodiesel by recovering nutrients from wastewater while simultaneously removing organic matters through cultivating oleaginous microorganisms was explored. For the microbial biogas production, the anaerobic co-digestion of a mixture of food waste and domestic wastewater (0.09, v/v) using an upflow anaerobic sludge blanket (UASB) reactor to generate renewable energy in form of biogas was investigated.

Achievements:

- Establishment of optimal process parameters for lipid productivity and removal of organics and nutrients from mixed (distillery and domestic) wastewater through laboratory-scale batch/reactor experiments.

- Estimating effects of yeast and microalgae on wastewater treatment and lipid production and optimizing mix ratio of yeast and microalgae.

- Exploring possibility to reuse (used) yeast seed culture medium with supplementary nutrients if necessary.

- Construction of effective oleaginous microbial consortium of yeast (Rhodosporidium toruloides) and autotrophic oleaginous microalgal strains.

- Anaerobic digestion of food waste using UASB reactor.

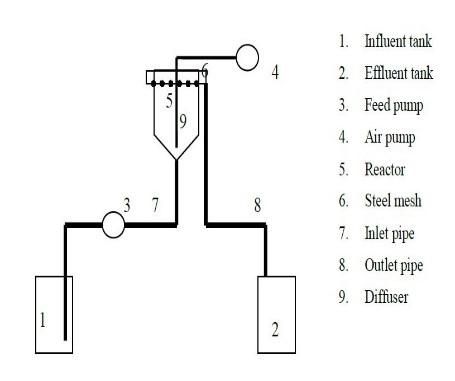

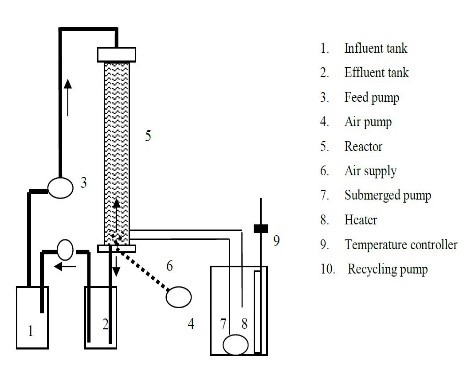

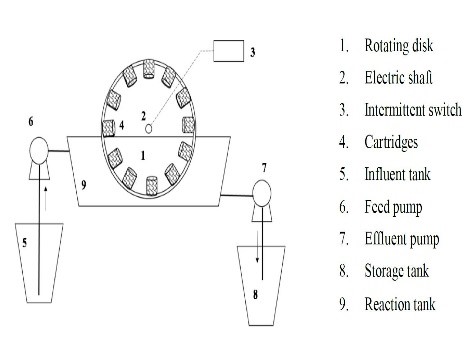

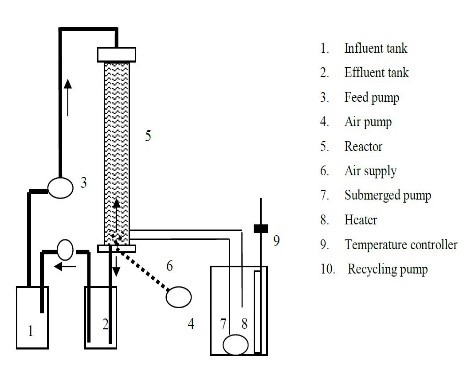

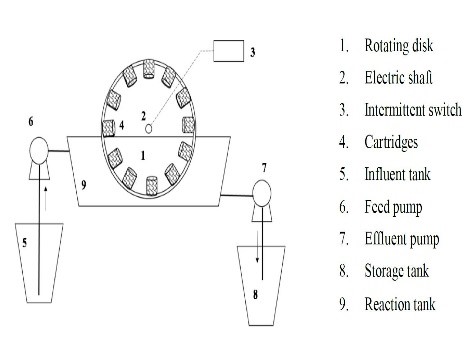

Wastewater Treatment – Bioremoval of Pharmaceutically Active Compounds (Emerging Micro-Pollutants)

|

|

|

| WRF fixed-bed reactor |

Countercurrent seepage bioreactor | Rotating suspension cartridge reactor |

Phthalate esters (PAEs) are industrial chemicals widely used as plasticizers in industrial, domestic, and medical applications. PAEs belong to newly emerging contaminants and are considered as endocrine disrupting chemicals (EDCs) due to their adverse effects on human and aquatic organisms’ fertility. PAEs such as di(2-ethylhexyl) phthalate (DEHP) can be easily released into the environment because they are physically rather than chemically bonded to the plastic products matrices.

On the other hand, pharmaceutically active compounds (PhACs) such as carbamazepine and naproxen, classified as micropollutants, have been detected in many water bodies worldwide. PhACs are hardly biodegraded (removal efficiency <10%) through the conventional activated sludge process and the white-rot fungus (WRF) is reported to degrade them efficiently. The WRF reactors have been applied to remove PhACs from wastewater, with the varied performances. In addition, it is still hard to maintain a long-term stable reactor performance considering the bacterial contamination. Under these circumstances, the enhancement of the removal performances of PhACs through WRF reactor under non-sterile conditions during long-term operation was investigated.

Achievements:

- Enhanced removal of carbamazepine and naproxen from wastewater by immobilized white-rot fungus (WRF) Phaenerochaete chrysosporium through batch and reactor experiments under non-sterile condition.

- Enzyme (LiP and MnP) kinetics study to optimize conditions for better removal efficiencies.

- Enhanced removal of other micro-pollutants including ECDs (endocrine disrupters); PCPPs (pharmaceuticals and personal care products); Antibiotics and metabolites.

- Enhanced removal of DEHP from artificially contaminated water using indigenous bacterial isolate, Acinetobacter; Optimizing the DEHP biodegradation process, evaluating growth kinetics and biodegradation pathway for DEHP by the isolate and evaluating the effects of microelements on DEHP biodegradation.

REFERENCES (Since 2015 only), mainly related to biological remediation of contaminants/pollutants in water and subsurface (soil and groundwater) environments:

- Li, J., C. Wu, S-H. Chen, Q. Lu, H. Shim, X. Huang, C. Jia, and S. Wang. 2020. Enriching indigenous microbial consortia as a promising strategy for xenobiotics’ cleanup. Journal of Cleaner Production. In press (accepted). DOI: https://doi.org/10.1016/j.jclepro.2020.121234

- Lu, Q., X. Zou, J. Liu, Z. Liang, H. Shim, R. Qiu, and S. Wang. 2019. Inhibitory effects of heavy metal ions on reductive dechlorination of polychlorinated biphenyls and perchloroethene in distinct organohalide-respiring bacteria. Environment International. 135. 105373. https://doi.org/10.1016/j.envint.2019.105373

- Chan, P.C., Q. Lu, R.A. de Toledo, J-D. Gu, and H. Shim. 2019. Improved anaerobic co-digestion of food waste and domestic wastewater by copper supplementation – microbial community identification and effluent quality analysis. Science of the Total Environment. 670:337-344. DOI: 10.1016/j.scitotenv.2019.03.081

- Lu, Q., L. Qiu, L. Yu, S. Zhang, R.A. de Toledo, H. Shim, and S. Wang. 2019. Microbial transformation of chiral organohalides: Distribution, microorganisms and mechanisms. Journal of Hazardous Materials. 368:849-861.

- Zhou, Z., B. Liang, L-Y. Wang, J-F. Liu, B-Z. Mu, H. Shim, and J-D. Gu. 2019. Identify the core bacterial microbiome of hydrocarbon degradation and a shift of dominant methanogenesis pathways in the oil and aqueous phases of petroleum reservoirs of different temperatures from China. Biogeosciences. 16(21):4229-4241. https://doi.org/10.5194/bg-16-4229-2019

- De Toledo, R.A., U.H. Chao, T.T. Shen, Q. Lu, X. Li, and H. Shim. 2019. Reutilization of sewage sludge, waste scrap tires, and wood chips as sorbents to remove volatile organic compounds, plasticizer, and pharmaceutically active compound from contaminated environment. Environmental Science and Pollution Research. 26(12):11591-11604. DOI: 10.1007/s11356-018-2877-2

- De Toledo, R.A., X. Li, K.I. Wong, and H. Shim. September 2018. Biological removal of naproxen from non-sterile synthetic wastewater using Phanerochaete chrysosporium. In: Naproxen: Chemistry, Clinical Aspects and Effects. Nova Science Publishers, Inc. Chapter 4. pp.101-129.

- Chan, P.C., R.A. de Toledo, and H. Shim. 2018. Anaerobic co-digestion of food waste and domestic wastewater – Effect of intermittent feeding on short and long chain fatty acids accumulation. Renewable Energy. 124:129-135. DOI: 10.1016/j.renene.2017.07.029.

- De Toledo, R.A., J. Xu, U.H. Chao, and H. Shim. 2017. EFFECTS OF MANGANESE AND FERRIC IONS ON THE DEGRADATION OF DI-2-ETHYLHEXYL PHTHALATE (DEHP) BY ACINETOBACTER sp. SN13. In: Micropollutants: Sources, Ecotoxicological Effects and Control Strategies. Nova Science Publishers, Inc. Chapter 2. pp.45-68.

- Lu, Q., R.A. de Toledo, F. Xie, J. Li, and H. Shim. 2017. Reutilization of waste scrap tyre as the immobilization matrix for the enhanced bioremoval of a monoaromatic hydrocarbons, methyl tert-butyl ether, and chlorinated ethenes mixture from water. Science of the Total Environment. 583:88-96.

- Xu, J., Q. Lu, R.A. de Toledo, and H. Shim. 2017. Degradation of di-2-ethylhexyl phthalate (DEHP) by an indigenous isolate Acinetobacter sp. International Biodeterioration & Biodegradation. 117:205-214.

- Li, J., R.A. de Toledo, and H. Shim. 2017. Multivariate optimization for the simultaneous bioremoval of BTEX and chlorinated aliphatic hydrocarbons by Pseudomonas plecoglossicida. Journal of Hazardous Materials. 321:238-246. DOI: 10.1016/j.jhazmat.2016.09.020

- Ling, J., Y. Tian, R.A. de Toledo, and H. Shim. 2017. Cost reduction for the lipid production from distillery and domestic mixed wastewater by Rhodosporidium toruloides via the reutilization of spent seed culture medium. Energy. 136:135-141. DOI: 10.1016/j.energy.2016.04.008

- Ling, J., R.A. de Toledo, and H. Shim. 2016. Biodiesel production from wastewater using oleaginous yeast and microalga. In Environmental Materials and Waste – Resource Recovery and Pollution Prevention [EMW – RR and PP]. M.N.V. Prasad and K. Shih (eds). Publisher Elsevier USA. Ch. 8. pp.180-213.

- Li, X., J. Xu, R.A. de Toledo, and H. Shim. 2016. Enhanced carbamazepine removal by immobilized Phanerochaete chrysosporium in a novel rotating suspension cartridge reactor under non-sterile condition. International Biodeterioration & Biodegradation. 115:102-109. DOI: 10.1016/j.ibiod.2016.08.003

- Xie, F., Q. Lu, R.A. de Toledo, and H. Shim. 2016. Enhanced simultaneous removal of MTBE and TCE mixture by Paracoccus sp. immobilized on waste silica gel. International Biodeterioration & Biodegradation. 114:222-227. DOI: 10.1016/j.ibiod.2016.07.003

- Kwon, K., H. Shim, W. Bae, J. Oh, and J. Bae. 2016. Simultaneous Biodegradation of Carbon Tetrachloride and Trichloroethylene in a Coupled Anaerobic/Aerobic Biobarrier. Journal of Hazardous Materials. 313:60-67.

- Lu, Q., R.A. de Toledo, and H. Shim. 2016. Effect of COD/TP ratio on biological nutrient removal between A2O and SBR process coupled with microfiltration and effluent reuse potential. Environmental Technology. 37(12):1461-1466.

- Ling, J., S. Nip, R.A. de Toledo, Y. Tian, and H. Shim. 2016. Evaluation of specific lipid production and nutrients removal from wastewater by Rhodosporidium toruloides and biodiesel production from wet biomass via microwave irradiation. Energy. 108:185-194. DOI: 10.1016/j.energy.2015.05.141

- Li, X., J. Xu, R.A. de Toledo, and H. Shim. 2015. Enhanced removal of naproxen and carbamazepine from wastewater through a novel countercurrent seepage bioreactor immobilized with Phaenerochaete chrysosporium under non-sterile conditions. Bioresource Technology. 197:465-474.

視像簽約!澳大與中科院海洋研究所成立海洋環境與工程聯合實驗室

澳門大學今(24)日舉行“澳門大學—中國科學院海洋研究所合作框架協議簽署儀式”,成立海洋環境與工程聯合實驗室。雙方將充分發揮在海洋環境與生態、海洋工程等領域的研究優勢,促進彼此在相關科學領域的研究與發展,為澳門及粵港澳大灣區的科技創新帶來裨益。是次簽署通過視像進行,是澳大歷史上首次以視像會議的形式舉行簽約儀式,此舉充分體現了澳大在科技交流合作在任何時候都“不停步”。

中國科學院海洋研究所在是內地第一個專門從事海洋科學研究的國立機構,是國家規模最大、綜合實力最強的綜合海洋研究機構之一。中科院海洋研究所的研究領域涵蓋廣泛,分別設有5個中國科學院重點實驗室、3個國家級科研平台、2個功能實驗室及7個研究支撐單元,在國家海洋基礎研究領域做出了許多奠基性和開創性的工作。

澳大校長宋永華致辭表示,澳大開展海洋環境與工程的研究,既因應澳門和大灣區的重大需求,又著眼於國際前沿科學研究。通過此次與中科院海洋研究所的合作,將共同建設高水準科研合作平台,共用資源、發揮所長,促進共同發展,為澳門、大灣區乃至全國的海洋環境與工程領域發展貢獻力量。雙方將利用各自領域的研究優勢,促進在海洋環境與工程中的近海環境生態,海洋地質,海洋多圈層動力與區域海洋環境調節機制,城市自然災害防治和海洋工程等領域科研的協同發展,強化科研人才的聯合培養與交流合作,促進雙方科技成果的轉化、提升科技產業競爭能力,同時開展國際交流,強化與葡萄牙在海洋領域的合作。

中科院海洋研究所所長王凡表示,是次合作迎合了國家對海洋發展的迫切需求,是新一輪發展的機遇期。標誌著中國科學院海洋研究所與澳門大學的合作踏出了實質性一步。澳大是著名的國際化綜合大學,在海洋環境與生態、海洋工程等領域有獨特的學科和實力優勢。這次是著名高校與著名科研機構的一次戰略性強強合作,優勢互補,意義重大。雙方合作願望強烈,將充分發揮特長優勢,開展海洋環境與工程研究領域多學科交叉的創新性合作研究,共同服務澳門和大灣區。

為支持澳門繁榮穩定,實現經濟社會可持續發展,中央人民政府於2015年將澳門特別行政區海域面積明確為85平方公里。澳門海域水系複雜,受海水、珠江徑流及風暴潮影響明顯,如何有效利用和保護區域海洋生態資源,是澳門可持續發展面臨的巨大挑戰。澳大高度重視海洋環境、海洋工程、和防災減災方面的學術前沿課題。為深入開展及推進區域海洋相關課題的學術交流與合作,助力澳門社會乃至粵港澳大灣區的長遠發展,澳大於2019年在科技學院成立區域海洋研究中心。

儀式上,宋永華和王凡分別代表雙方簽署了合作框架協議,海洋環境與工程聯合實驗室成立,標誌著澳門大學與中科院海洋研究所的合作由此全面開啟。是次儀式主持人為澳大副校長葛偉。

新聞來源:研究服務及知識轉移辦公室

https://www.um.edu.mo/zh-hant/news-centre/news-and-events/news-and-press-releases/detail/50023/

澳大與中科院海洋研究所成立海洋環境與工程聯合實驗室

雙方進行視像會議

宋永華致辭

合影

澳門大學參與南方海洋科學與工程廣東省實驗室(珠海) 第二批合作共建單位簽約儀式

12月03日,南方海洋科學與工程廣東省實驗室(珠海)舉行第二批合作共建單位簽約儀式。第二批合作共建單位包括香港、澳門、廣東等地高校,以及國家海洋環境預報中心和相關企事業單位等14家。廣東省基礎與應用基礎研究基金委主任曾路、珠海市副市長閻武、中山大學常務副校長孫冬柏出席會議並致辭。主持人中國科學院院士、南方海洋實驗室主任陳大可介紹南方海洋實驗室基本情況,實驗室以對標國際最優、最好、最先進的海洋實驗室、集聚全球創新人才、突出原始創新導向為目標,以“成熟一個、建設一個”為原則,布局建設具有國際領先水平的公共實驗平台和研究團隊。

為進一步加快南方海洋實驗室建設,統籌海洋領域科技創新資源,推進合作共建,集智創新,南方海洋實驗室邀請澳門大學加入南方海洋實驗室共建單位,出席第二批合作共建單位簽約儀式,共同為國家海洋事業出謀劃策,共襄盛舉。澳門大學代表副校長葛偉參與共建單位簽約儀式,就推進南方海洋科學研究與創新、支持粵港澳大灣區的科研及管理等方面工作展開深入交流。

簽約儀式結束後,實驗室召開了共建單位交流座談會,各共建單位代表分別介紹了各自合作基礎、擬合作領域、方向、可共享平台等內容,與省實驗室主任陳大可院士展開討論交流。澳門大學代表介紹了澳門大學基本情況,着重介紹了教學與科研發展,進一步介紹了澳門大學國家重點實驗室、區域海洋中心建設情況與發展戰略,對海洋相關科研課題與儀器設備進行講解。期後,中國科學院院士、南方海洋實驗室主任陳大可與澳門大學代表和其餘共建單位代表進行會談,並提出希望各方在未來的科研項目上加深合作,積極參與申報國家級重大科研項目與建設,以南方海洋實驗室和「海洋強國」戰略為契機,抓住機遇,面對挑戰,努力推動國家海洋經濟和生態可持續發展,為祖國繁榮、粵港澳大灣區發展、兩岸三地融合發揮更加積極的作用。

出席參訪活動的各方代表還有:

邰忠智 中山大學副校長,王雷珠海市科技創新局局長,以及廣東省科技廳、珠海市、南方海洋實驗室、各共建單位代表。

出席參訪活動的澳門大學代表還有:

申平 助理教授。

澳門大學副校長葛偉參與簽約儀式

澳門大學副校長葛偉參與簽約代表合影

各簽約單位代表合影

共建單位交流會

澳門海事及水務局代表團參訪澳門大學

11月5日,澳門海事及水務局副局長郭虔率代表團參訪澳門大學,獲澳門大學校長宋永華校長熱情接待。出席參訪活動的澳門海事及水務局代表包括海域管理廳廳長林純、海洋技術處處長黃昆侖及海域管理廳高級技術員鄭漢樺。

出席活動的澳門大學代表包括,澳門大學科技學院院長須成忠、土木與環境工程系主任兼區域海洋研究中心代主任周萬歡、中華醫藥研究院教授李銘源、土木及環境工程系助理教授張平、智慧城市物聯網國家重點實驗室助理教授高亮及工商管理學院綜合度假村及旅遊管理學系助理教授邱天然。

澳門大學科技學院院長須成忠及土木與環境工程系主任兼區域海洋研究中心代主任周萬歡向代表團介紹了關於澳門大學區域海洋中心建設初步成果以及規劃發展。隨後,澳門代表團成員分別介紹了關於城市大數據與智慧技術、海洋土木工程發展與現狀、中醫藥研究與產業經濟發展、水域生態環境監測與用水安全、近海城市公共安全與水災害防治、開發海洋旅遊與增強澳門特色旅遊等方面的最新科研進展。

其後,澳門大學校長宋永華近一步補充了區域海洋中心的發展願景以及人才梯隊建設方案,並介紹了區域海洋研究中心以及智慧城市物聯網國家重點實驗室的發展定位和目標。郭虔副局長介紹了澳門海事及水務局成立至今的歷史及發展,也對目前澳門大學區域海洋中心的發展表達了贊許和期待,並對進一步推動澳門水務與海事相關的科技專案,大力推動澳門海洋經濟表達了共同合作的意願。雙方一致表示,澳門大學與澳門海事及水務局應進一步增進交流,開展深層次的合作,共同開展澳門海洋產業經濟與災害防治的研究,共同推動澳門相關領域的進步與發展。

過去活動

重要建築物之結構分析及保護方案

澳門世界遺產歷史建築物

澳門在2003年後隨著博彩業的開放,各項大型酒店及相關建設得到快速的發展。在另一方面,聯合國教科文組織亦於2005年宣布了澳門舊城區成功被列入為世界遺產名錄中。而應對風災對重要建築物的影響是其中一項重點工作。本澳現有重要的結構建築物大致可以分為三大類型:(一)以磚木或石材建成的古建築物丶(二)鋼筋混凝土建築物及(三)鋼及金屬建築物。對於用不同材料建造的建築物,其相關抗風處理亦會有所不同。因此本澳有必要完善對相關重要建築物在抗風方面的能力及保護加固方面作更多的研究,以規模業界在相關工作之標準。

砌體結構是澳門及世界上最常見的一種建築結構,但對於砌體結構建築特性的系統性科學研究還較少。本項目針對現有建築修復與保護的需要,特別是對於有價值的古代砌體結構建築,同時結合節能環保,經濟效率,和文化價值等多方面考慮,探索新型複合材料的創新加固技術在土木工程領域的應用研究。纖維增强無機基質新型複合材料(在文獻中作爲TRM,FRCM等的統稱)因其良好的兼容性與耐久性最近受到了土木工程學界很大的關注。研究針對不同的纖維增强無機基質的新型複合材料的特性和加固效果,運用國際先進的實驗和數值模擬技術,探索新型複合材料的創新加固技術替代傳統古代建築修復和保護技術的潜力,提高建築保護修復的安全性和可靠性,降低建築修復的風險和工作量。[1-3]

纖维材料加強之砌體實驗試件

為了應對氣候變化所產生的各種自然荷載(例如颱風、温度變化等自然現象)對建築物的影響,新型材料及高強度材料在建築上之應用需求有著上升的趨勢。高強度鋼材由於其優勝之強度重量比特性,其應用在鋼結構設計中的比例日益提升。由於其高強度的特性,在設計某些受壓構件時,其承載能力往往會受制於其細長比系數。為更有效地提升其承載能力,在此情況下可以加入適當設計之加勁板。由於現有對鋼結構加勁板之設計公式大多數是基於以往低至中等強度的鋼材所得到的,有關於設計高強度鋼材加勁板的公式 相对比較少。因此有必要對高強度鋼材設計進行更多之實驗及分析研究,進一步提出適用於業界之設計方法及公式,提升設計效率和安全。[4] 對於現存的重要鋼結構建築物而言,高强纖維材料之應用不但能有效地降低裂紋之生長,並且能夠提高現有構件之強度。[5]

鋼結構不同類型之加勁板設計

相關文章

- Wang, X., Lam, C.C., Iu, V.P. (2019). Comparison of different types of TRM composites for strengthening masonry panels, Construction and Building Materials, 219, pp. 184-194

- Wang, X., Lam, C.C., Iu, V.P. (2018). Experimental investigation of in-plane shear behaviour of grey clay brick masonry panels strengthened with SRG. Engineering Structures, 162, 84-96

- Wang, X, Ghiassi, B, Oliveira, D. V., Lam, C.C. (2017). Modelling the nonlinear behaviour of masonry walls strengthened with textile reinforced mortars. Engineering Structures, 134. pp. 11-24

- Lam, C. C., Yam, M.C.H., Fang, C. (2017). Strength and behavior of reinforced double-coped beams against local web buckling. Journal of Constructional Steel Research, 138. pp. 38-50

- Lam, A.C.C., Yam, M.C.H., Cheng, J.J.R. and Kennedy, G.D., (2010) Study of stress intensity factor of a crack steel plate with a single-side CFRP composite patching, Journal of Composites for Construction, ASCE, Vol. 14(6), pp. 791-803

鋼構材成形過程(冷成形、三維打印技術)對鋼結構性能的影響

Cold-formed metal structures

No longer a Dream for predicting geometric imperfection, residual stresses and strength enhancement in cold-formed steel structures realistically! A deterministic approach with advanced numerical modeling of manufacturing processes is a solution.

Million tons of cold-formed metal building products are used in construction industry around the world each year. This trend is kept increasing due to their construction efficiency in Modular integrated Construction (MiC). The structural performance of cold-formed thin-walled metal structures is known to be sensitive to initial imperfections which include both geometrical imperfection and cold work due to forming. Traditionally, this cold work effect has been taken into account by using separate specifications of mechanical properties for the flat portions and the corner regions in conjunction with idealized residual stresses models which are based on inappropriate assumptions disregarding the effect of the manufacturing process. Indeed, various cold-formed sections are fabricated by different manufacturing processes (Figs. 1 & 2). Hence, a research has been being carried out to seek for the solution to overcome this shortcoming.

|

| Fig 1. Manufacturing process of roll-formed tubes |

Coiling Uncoiling & Flattening Press Braking |

| Fig 2. Manufacturing process of press-braked sections |

Dr. Quach’s research has been focused on the development of various scientific tools (i.e. analytical models, empirical models, and hybrid analytical-finite element approaches) to accurately model manufacturing processes and quantify initial imperfections and the cold work effect (i.e., residual stresses and plastic strains) and in various types of cold-formed members (e.g. channels and hollow sections). The main contribution from this research is to correct the major deficiencies in existing knowledge and existing design approaches by using these proposed tools. The findings confirm the effect of the manufacturing process on the mechanical and structural performance of cold-formed metal members. The proposed methods/tools can be used to predict geometric imperfections, residual stresses and strength enhancement in cold-formed metal structures realistically.

An integration of these proposed scientific tools forms a novel and unified approach for the analysis and design of cold-formed thin-walled structures. This new approach can be used for optimizing the forming parameters of cold-formed steel sections and will greatly reduce the need for laboratory testing in the development of design rules.

The aforementioned research is a large study involving various parts of research, and is conducted through various projects funded by the university and the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of Macao S.A.R. This research is being developed at three main directions:

(a) Stress-strain models of thin sheet metals;

(b) Simulations and Predictions for enhanced strengths of cold-worked materials;

(c) Simulations and Predictions for initial imperfections (including geometrical imperfections, residual stresses, plastic strains) in cold-formed members and their effect on structural performance (Figs. 3~8).

|

|

| Fig 3. Finite element-based method: Numerical tube forming of EHS tubes |

Fig 4. Advanced finite element approach: Numerical stub column test of EHS |

|

|

| Fig 5. Finite element-based method: Numerical press braking |

Fig 6. Advanced finite element approach: Nonlinear buckling analysis |

|

|

| Fig 7. Numerically predicted local imperfections in an EHS | Fig 8. FE predicted stub-column behavior of an EHS |

3D printed metal structural members

Additive manufacturing, commonly known as 3D printing, is an evolutional technology in the manufacturing industry. This technology has already been embraced by different industries, such as aerospace and biomedical engineering, and the recent advance in this technology has generated a vast of societal excitement for its future. Despite the exciting prospect of its application in civil engineering, additive manufacturing technology is still at a perceived stage for construction industry. The benefits and potential in construction industry are rarely known in the field at this stage. This research aims to investigate the mechanical properties and structural performance of additively manufactured metal tubular sections (see Figs. 9 and 10). So far, high strength steel tubular stub columns additively manufactured by selective laser melting (SLM) with three different scanning patterns, have been tested. The anisotropy on mechanical properties has been examined through tensile coupon tests in both longitudinal and transverse directions. The influences of scanning patterns on mechanical properties and structural behavior of as-printed high strength steel tubular sections stub columns were also investigated. The test results have been used to assess the applicability of existing design provisions that originally developed for conventionally produced hot-rolled and cold-formed steel tubular sections to the additively manufactured high strength steel tubular sections.

|

|

| Fig 9. 3D printing of metals | Fig 10. 3D printed stainless steel tubes |

REFERENCES

(** Research students or Post-Doc from University of Macau. ^Corresponding author)

- Yan, J.J.**, Song, H., Dong, Y.P., Quach^, W.M. , and Yan^, M. (2020), High strength (~2000 MPa) or highly ductile (~11%) additively manufactured H13 by tempering at different conditions, Materials Science and Engineering A, 773, 138845. [Q1 in “Materials science, Multidisciplinary”. Q1 in “Metallurgy & metallurgical eng.”]

- Yao, Y.**, Quach^, W.M., and Young, B. (2019), Cross-section behavior of cold-formed steel elliptical hollow sections – a numerical study, Engineering Structures, 201, 109797. [Q1 in Civil Eng.]

- Cai, Y., Quach^, W.M., and Young, B. (2019), Experimental and numerical investigation of concrete-filled hot-finished and cold-formed steel elliptical tubular stub columns, Thin-Walled Structures, 145, 106437. [Q1 in Civil Eng.]

- Yao, Y.**, Quach^, W.M., and Young, B. (2019), Finite element-based method for residual stresses in cold-formed steel hollow sections, Engineering Structures, 188, 24-42. [Q1 in Civil Eng.]

- Yan, J.J.**, Chen^, M.T.**, Quach, W.M., Yan, M., and Young, B. (2019), Mechanical properties and cross-sectional behavior of additive manufactured high strength steel tubular sections, Thin-Walled Structures, 144, 106158. [Q1 in Civil Eng.]

- Cai, Y., Quach^, W.M., Chen, M.T., and Young, B. (2019), Behavior and design of cold-formed and hot-finished steel elliptical tubular stub columns, Journal of Constructional Steel Research, 156, 252-265. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Yan, J.J.**, Zhou, Y.H., Gu, R.N., Zhang, X.M., Quach^, W.M. , and Yan^, M. (2019), A comprehensive study of steel powders (316L, H13, P20 and 18Ni300) for their selective laser melting additive manufacturing, Metals, 9(86), pp.1-20. [Q1 in Metallurgy & Metallurgical Eng.]

- Abambres^, M., and Quach, W.M. (2016), Residual Stresses in Steel Members: A Review of Available Analytical Expressions, International Journal of Structural Integrity, 7(1), pp.70-94. [Q3 in Civil & Structural Eng. Q3 in Mechanical Eng., according to SJR.]

- Quach, M., and Young^, B. (2015), Material properties of cold-formed and hot-finished elliptical hollow sections, Advances in Structural Engineering, 18(7), pp.1101-1114. [Q2 in Civil & Structural Eng. Q2 in Building & Construction, according to SJR.]

- Quach^, M., and Huang**, J.F. (2014), Two-stage stress-strain models for light-gauge steels, Advances in Structural Engineering, 17(7), pp.937-949. [Q2 in Civil & Structural Eng. Q2 in Building & Construction, according to SJR.]

- Quach^, M., and Qiu**, P. (2014), Strength and ductility of corner materials in cold-formed stainless steel sections, Thin-Walled Structures, 83, pp.28-42. [Q1 in Civil Eng.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2010), Effect of the manufacturing process on the behaviour of press-braked thin-walled steel columns, Engineering Structures, 32, pp.3501-3515. [Q1 in Civil Eng.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2009), Residual stresses in press-braked stainless steel sections – I: Coiling and uncoiling of sheets, Journal of Constructional Steel Research, 65, pp.1803-1815. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2009), Residual stresses in press-braked stainless steel sections – II: Press-braking operations, Journal of Constructional Steel Research, 65, pp.1816-1826. [Q1 in Civil Eng. Q1 in Construction & Building Technology.]

- Quach^, W. M., and Qiu, P. (2009), Accurate prediction of mechanical properties for cold-formed stainless steel section, Journal of Yantai University, Natural Science and Engineering Edition, 22(3), pp.217-228.

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2008), Three-stage full-range stress-strain model for stainless steels, Journal of Structural Engineering, ASCE, 134(9), pp.1518-1527. [Q1 in Civil & Structural Eng. Q1 in Building & Construction, according to SJR.]

- Quach^, W. M., Teng, J. G., and Chung, K. F. (2007), Finite element predictions of residual stresses in cold-formed steel sections, Progress in Steel Building Structures, 9(3), pp.26-32.

- Quach, W. M., Teng^, J. G., and Chung, K. F. (2006), Finite element predictions of residual stresses in press-braked thin-walled steel sections, Engineering Structures, 28, pp.1609-1619. [Q1 in Civil Eng.]

新的觀點:利用微生物清理受污染的環境

Combined (Bio)Remediation of Environment Contaminated with Mixed Wastes (BTEX/CAHs/MTBE)

|

|

|

| TCE | BTEX | MTBE |

Chlorinated aliphatic hydrocarbons (e.g., TCE), monoaromatic hydrocarbons (e.g., BTEX), and MTBE are major soil and water pollutants as a result of their widespread anthropogenic use. Soil contamination is of particular concern as it results in offsite contamination of groundwater and surface waters by migration of contaminants through and with soil materials. Co-contamination of soil with the mixed pollutants allows for the application of bioremediation to achieve their simultaneous mineralization.

Achievements:

- Isolating indigenous microorganisms capable of degrading BTEX / CAHs / MTBE mixture.

- Construction of effective microbial consortium.

- Establishing optimal process parameters for mixture degradation through laboratory-scale batch/reactor experiments.

- Enhanced removal through microbial immobilization on waste material (e.g., scrap tire, silica gel).

- Determining how interaction (stimulatory or inhibitory) affects DCE and/or TCE co-metabolism and co-metabolizing microbial community structure in the presence of MTBE.

- Identifying microorganisms responsible for MTBE/chloroethenes co-metabolism using culture and biomolecular methods.

- Developing integrated remediation technology that can meet the regional regulation/standards to be set and strengthened in the near future.

Microbial Biodiesel(/Biogas) Production Simultaneously with Enhanced Wastewater Treatment (and from Food Waste)

|

|

| Biodiesel Production | Biogas Production |

For the purpose of environmentally sustainable development, the recovery of resource or energy from wastes has attracted worldwide attention these days. The wastewater generated from food industries is more difficult to treat than the domestic wastewater due to their high organic loads. For the microbial biodiesel production, the possibility of developing a pre-treatment process which could produce microbial lipid that could be converted to biodiesel by recovering nutrients from wastewater while simultaneously removing organic matters through cultivating oleaginous microorganisms was explored. For the microbial biogas production, the anaerobic co-digestion of a mixture of food waste and domestic wastewater (0.09, v/v) using an upflow anaerobic sludge blanket (UASB) reactor to generate renewable energy in form of biogas was investigated.

Achievements:

- Establishment of optimal process parameters for lipid productivity and removal of organics and nutrients from mixed (distillery and domestic) wastewater through laboratory-scale batch/reactor experiments.

- Estimating effects of yeast and microalgae on wastewater treatment and lipid production and optimizing mix ratio of yeast and microalgae.

- Exploring possibility to reuse (used) yeast seed culture medium with supplementary nutrients if necessary.

- Construction of effective oleaginous microbial consortium of yeast (Rhodosporidium toruloides) and autotrophic oleaginous microalgal strains.

- Anaerobic digestion of food waste using UASB reactor.

Wastewater Treatment – Bioremoval of Pharmaceutically Active Compounds (Emerging Micro-Pollutants)

|

|

|

| WRF fixed-bed reactor |

Countercurrent seepage bioreactor | Rotating suspension cartridge reactor |

Phthalate esters (PAEs) are industrial chemicals widely used as plasticizers in industrial, domestic, and medical applications. PAEs belong to newly emerging contaminants and are considered as endocrine disrupting chemicals (EDCs) due to their adverse effects on human and aquatic organisms’ fertility. PAEs such as di(2-ethylhexyl) phthalate (DEHP) can be easily released into the environment because they are physically rather than chemically bonded to the plastic products matrices.

On the other hand, pharmaceutically active compounds (PhACs) such as carbamazepine and naproxen, classified as micropollutants, have been detected in many water bodies worldwide. PhACs are hardly biodegraded (removal efficiency <10%) through the conventional activated sludge process and the white-rot fungus (WRF) is reported to degrade them efficiently. The WRF reactors have been applied to remove PhACs from wastewater, with the varied performances. In addition, it is still hard to maintain a long-term stable reactor performance considering the bacterial contamination. Under these circumstances, the enhancement of the removal performances of PhACs through WRF reactor under non-sterile conditions during long-term operation was investigated.

Achievements:

- Enhanced removal of carbamazepine and naproxen from wastewater by immobilized white-rot fungus (WRF) Phaenerochaete chrysosporium through batch and reactor experiments under non-sterile condition.

- Enzyme (LiP and MnP) kinetics study to optimize conditions for better removal efficiencies.

- Enhanced removal of other micro-pollutants including ECDs (endocrine disrupters); PCPPs (pharmaceuticals and personal care products); Antibiotics and metabolites.

- Enhanced removal of DEHP from artificially contaminated water using indigenous bacterial isolate, Acinetobacter; Optimizing the DEHP biodegradation process, evaluating growth kinetics and biodegradation pathway for DEHP by the isolate and evaluating the effects of microelements on DEHP biodegradation.

REFERENCES (Since 2015 only), mainly related to biological remediation of contaminants/pollutants in water and subsurface (soil and groundwater) environments:

- Li, J., C. Wu, S-H. Chen, Q. Lu, H. Shim, X. Huang, C. Jia, and S. Wang. 2020. Enriching indigenous microbial consortia as a promising strategy for xenobiotics’ cleanup. Journal of Cleaner Production. In press (accepted). DOI: https://doi.org/10.1016/j.jclepro.2020.121234

- Lu, Q., X. Zou, J. Liu, Z. Liang, H. Shim, R. Qiu, and S. Wang. 2019. Inhibitory effects of heavy metal ions on reductive dechlorination of polychlorinated biphenyls and perchloroethene in distinct organohalide-respiring bacteria. Environment International. 135. 105373. https://doi.org/10.1016/j.envint.2019.105373

- Chan, P.C., Q. Lu, R.A. de Toledo, J-D. Gu, and H. Shim. 2019. Improved anaerobic co-digestion of food waste and domestic wastewater by copper supplementation – microbial community identification and effluent quality analysis. Science of the Total Environment. 670:337-344. DOI: 10.1016/j.scitotenv.2019.03.081

- Lu, Q., L. Qiu, L. Yu, S. Zhang, R.A. de Toledo, H. Shim, and S. Wang. 2019. Microbial transformation of chiral organohalides: Distribution, microorganisms and mechanisms. Journal of Hazardous Materials. 368:849-861.

- Zhou, Z., B. Liang, L-Y. Wang, J-F. Liu, B-Z. Mu, H. Shim, and J-D. Gu. 2019. Identify the core bacterial microbiome of hydrocarbon degradation and a shift of dominant methanogenesis pathways in the oil and aqueous phases of petroleum reservoirs of different temperatures from China. Biogeosciences. 16(21):4229-4241. https://doi.org/10.5194/bg-16-4229-2019

- De Toledo, R.A., U.H. Chao, T.T. Shen, Q. Lu, X. Li, and H. Shim. 2019. Reutilization of sewage sludge, waste scrap tires, and wood chips as sorbents to remove volatile organic compounds, plasticizer, and pharmaceutically active compound from contaminated environment. Environmental Science and Pollution Research. 26(12):11591-11604. DOI: 10.1007/s11356-018-2877-2

- De Toledo, R.A., X. Li, K.I. Wong, and H. Shim. September 2018. Biological removal of naproxen from non-sterile synthetic wastewater using Phanerochaete chrysosporium. In: Naproxen: Chemistry, Clinical Aspects and Effects. Nova Science Publishers, Inc. Chapter 4. pp.101-129.

- Chan, P.C., R.A. de Toledo, and H. Shim. 2018. Anaerobic co-digestion of food waste and domestic wastewater – Effect of intermittent feeding on short and long chain fatty acids accumulation. Renewable Energy. 124:129-135. DOI: 10.1016/j.renene.2017.07.029.

- De Toledo, R.A., J. Xu, U.H. Chao, and H. Shim. 2017. EFFECTS OF MANGANESE AND FERRIC IONS ON THE DEGRADATION OF DI-2-ETHYLHEXYL PHTHALATE (DEHP) BY ACINETOBACTER sp. SN13. In: Micropollutants: Sources, Ecotoxicological Effects and Control Strategies. Nova Science Publishers, Inc. Chapter 2. pp.45-68.

- Lu, Q., R.A. de Toledo, F. Xie, J. Li, and H. Shim. 2017. Reutilization of waste scrap tyre as the immobilization matrix for the enhanced bioremoval of a monoaromatic hydrocarbons, methyl tert-butyl ether, and chlorinated ethenes mixture from water. Science of the Total Environment. 583:88-96.

- Xu, J., Q. Lu, R.A. de Toledo, and H. Shim. 2017. Degradation of di-2-ethylhexyl phthalate (DEHP) by an indigenous isolate Acinetobacter sp. International Biodeterioration & Biodegradation. 117:205-214.

- Li, J., R.A. de Toledo, and H. Shim. 2017. Multivariate optimization for the simultaneous bioremoval of BTEX and chlorinated aliphatic hydrocarbons by Pseudomonas plecoglossicida. Journal of Hazardous Materials. 321:238-246. DOI: 10.1016/j.jhazmat.2016.09.020

- Ling, J., Y. Tian, R.A. de Toledo, and H. Shim. 2017. Cost reduction for the lipid production from distillery and domestic mixed wastewater by Rhodosporidium toruloides via the reutilization of spent seed culture medium. Energy. 136:135-141. DOI: 10.1016/j.energy.2016.04.008

- Ling, J., R.A. de Toledo, and H. Shim. 2016. Biodiesel production from wastewater using oleaginous yeast and microalga. In Environmental Materials and Waste – Resource Recovery and Pollution Prevention [EMW – RR and PP]. M.N.V. Prasad and K. Shih (eds). Publisher Elsevier USA. Ch. 8. pp.180-213.

- Li, X., J. Xu, R.A. de Toledo, and H. Shim. 2016. Enhanced carbamazepine removal by immobilized Phanerochaete chrysosporium in a novel rotating suspension cartridge reactor under non-sterile condition. International Biodeterioration & Biodegradation. 115:102-109. DOI: 10.1016/j.ibiod.2016.08.003

- Xie, F., Q. Lu, R.A. de Toledo, and H. Shim. 2016. Enhanced simultaneous removal of MTBE and TCE mixture by Paracoccus sp. immobilized on waste silica gel. International Biodeterioration & Biodegradation. 114:222-227. DOI: 10.1016/j.ibiod.2016.07.003

- Kwon, K., H. Shim, W. Bae, J. Oh, and J. Bae. 2016. Simultaneous Biodegradation of Carbon Tetrachloride and Trichloroethylene in a Coupled Anaerobic/Aerobic Biobarrier. Journal of Hazardous Materials. 313:60-67.

- Lu, Q., R.A. de Toledo, and H. Shim. 2016. Effect of COD/TP ratio on biological nutrient removal between A2O and SBR process coupled with microfiltration and effluent reuse potential. Environmental Technology. 37(12):1461-1466.

- Ling, J., S. Nip, R.A. de Toledo, Y. Tian, and H. Shim. 2016. Evaluation of specific lipid production and nutrients removal from wastewater by Rhodosporidium toruloides and biodiesel production from wet biomass via microwave irradiation. Energy. 108:185-194. DOI: 10.1016/j.energy.2015.05.141

- Li, X., J. Xu, R.A. de Toledo, and H. Shim. 2015. Enhanced removal of naproxen and carbamazepine from wastewater through a novel countercurrent seepage bioreactor immobilized with Phaenerochaete chrysosporium under non-sterile conditions. Bioresource Technology. 197:465-474.

視像簽約!澳大與中科院海洋研究所成立海洋環境與工程聯合實驗室

澳門大學今(24)日舉行“澳門大學—中國科學院海洋研究所合作框架協議簽署儀式”,成立海洋環境與工程聯合實驗室。雙方將充分發揮在海洋環境與生態、海洋工程等領域的研究優勢,促進彼此在相關科學領域的研究與發展,為澳門及粵港澳大灣區的科技創新帶來裨益。是次簽署通過視像進行,是澳大歷史上首次以視像會議的形式舉行簽約儀式,此舉充分體現了澳大在科技交流合作在任何時候都“不停步”。

中國科學院海洋研究所在是內地第一個專門從事海洋科學研究的國立機構,是國家規模最大、綜合實力最強的綜合海洋研究機構之一。中科院海洋研究所的研究領域涵蓋廣泛,分別設有5個中國科學院重點實驗室、3個國家級科研平台、2個功能實驗室及7個研究支撐單元,在國家海洋基礎研究領域做出了許多奠基性和開創性的工作。

澳大校長宋永華致辭表示,澳大開展海洋環境與工程的研究,既因應澳門和大灣區的重大需求,又著眼於國際前沿科學研究。通過此次與中科院海洋研究所的合作,將共同建設高水準科研合作平台,共用資源、發揮所長,促進共同發展,為澳門、大灣區乃至全國的海洋環境與工程領域發展貢獻力量。雙方將利用各自領域的研究優勢,促進在海洋環境與工程中的近海環境生態,海洋地質,海洋多圈層動力與區域海洋環境調節機制,城市自然災害防治和海洋工程等領域科研的協同發展,強化科研人才的聯合培養與交流合作,促進雙方科技成果的轉化、提升科技產業競爭能力,同時開展國際交流,強化與葡萄牙在海洋領域的合作。

中科院海洋研究所所長王凡表示,是次合作迎合了國家對海洋發展的迫切需求,是新一輪發展的機遇期。標誌著中國科學院海洋研究所與澳門大學的合作踏出了實質性一步。澳大是著名的國際化綜合大學,在海洋環境與生態、海洋工程等領域有獨特的學科和實力優勢。這次是著名高校與著名科研機構的一次戰略性強強合作,優勢互補,意義重大。雙方合作願望強烈,將充分發揮特長優勢,開展海洋環境與工程研究領域多學科交叉的創新性合作研究,共同服務澳門和大灣區。

為支持澳門繁榮穩定,實現經濟社會可持續發展,中央人民政府於2015年將澳門特別行政區海域面積明確為85平方公里。澳門海域水系複雜,受海水、珠江徑流及風暴潮影響明顯,如何有效利用和保護區域海洋生態資源,是澳門可持續發展面臨的巨大挑戰。澳大高度重視海洋環境、海洋工程、和防災減災方面的學術前沿課題。為深入開展及推進區域海洋相關課題的學術交流與合作,助力澳門社會乃至粵港澳大灣區的長遠發展,澳大於2019年在科技學院成立區域海洋研究中心。

儀式上,宋永華和王凡分別代表雙方簽署了合作框架協議,海洋環境與工程聯合實驗室成立,標誌著澳門大學與中科院海洋研究所的合作由此全面開啟。是次儀式主持人為澳大副校長葛偉。

新聞來源:研究服務及知識轉移辦公室

https://www.um.edu.mo/zh-hant/news-centre/news-and-events/news-and-press-releases/detail/50023/

澳大與中科院海洋研究所成立海洋環境與工程聯合實驗室

雙方進行視像會議

宋永華致辭

合影

澳門大學參與南方海洋科學與工程廣東省實驗室(珠海) 第二批合作共建單位簽約儀式

12月03日,南方海洋科學與工程廣東省實驗室(珠海)舉行第二批合作共建單位簽約儀式。第二批合作共建單位包括香港、澳門、廣東等地高校,以及國家海洋環境預報中心和相關企事業單位等14家。廣東省基礎與應用基礎研究基金委主任曾路、珠海市副市長閻武、中山大學常務副校長孫冬柏出席會議並致辭。主持人中國科學院院士、南方海洋實驗室主任陳大可介紹南方海洋實驗室基本情況,實驗室以對標國際最優、最好、最先進的海洋實驗室、集聚全球創新人才、突出原始創新導向為目標,以“成熟一個、建設一個”為原則,布局建設具有國際領先水平的公共實驗平台和研究團隊。

為進一步加快南方海洋實驗室建設,統籌海洋領域科技創新資源,推進合作共建,集智創新,南方海洋實驗室邀請澳門大學加入南方海洋實驗室共建單位,出席第二批合作共建單位簽約儀式,共同為國家海洋事業出謀劃策,共襄盛舉。澳門大學代表副校長葛偉參與共建單位簽約儀式,就推進南方海洋科學研究與創新、支持粵港澳大灣區的科研及管理等方面工作展開深入交流。

簽約儀式結束後,實驗室召開了共建單位交流座談會,各共建單位代表分別介紹了各自合作基礎、擬合作領域、方向、可共享平台等內容,與省實驗室主任陳大可院士展開討論交流。澳門大學代表介紹了澳門大學基本情況,着重介紹了教學與科研發展,進一步介紹了澳門大學國家重點實驗室、區域海洋中心建設情況與發展戰略,對海洋相關科研課題與儀器設備進行講解。期後,中國科學院院士、南方海洋實驗室主任陳大可與澳門大學代表和其餘共建單位代表進行會談,並提出希望各方在未來的科研項目上加深合作,積極參與申報國家級重大科研項目與建設,以南方海洋實驗室和「海洋強國」戰略為契機,抓住機遇,面對挑戰,努力推動國家海洋經濟和生態可持續發展,為祖國繁榮、粵港澳大灣區發展、兩岸三地融合發揮更加積極的作用。

出席參訪活動的各方代表還有:

邰忠智 中山大學副校長,王雷珠海市科技創新局局長,以及廣東省科技廳、珠海市、南方海洋實驗室、各共建單位代表。

出席參訪活動的澳門大學代表還有:

申平 助理教授。

澳門大學副校長葛偉參與簽約儀式

澳門大學副校長葛偉參與簽約代表合影

各簽約單位代表合影

共建單位交流會

澳門海事及水務局代表團參訪澳門大學

11月5日,澳門海事及水務局副局長郭虔率代表團參訪澳門大學,獲澳門大學校長宋永華校長熱情接待。出席參訪活動的澳門海事及水務局代表包括海域管理廳廳長林純、海洋技術處處長黃昆侖及海域管理廳高級技術員鄭漢樺。

出席活動的澳門大學代表包括,澳門大學科技學院院長須成忠、土木與環境工程系主任兼區域海洋研究中心代主任周萬歡、中華醫藥研究院教授李銘源、土木及環境工程系助理教授張平、智慧城市物聯網國家重點實驗室助理教授高亮及工商管理學院綜合度假村及旅遊管理學系助理教授邱天然。

澳門大學科技學院院長須成忠及土木與環境工程系主任兼區域海洋研究中心代主任周萬歡向代表團介紹了關於澳門大學區域海洋中心建設初步成果以及規劃發展。隨後,澳門代表團成員分別介紹了關於城市大數據與智慧技術、海洋土木工程發展與現狀、中醫藥研究與產業經濟發展、水域生態環境監測與用水安全、近海城市公共安全與水災害防治、開發海洋旅遊與增強澳門特色旅遊等方面的最新科研進展。

其後,澳門大學校長宋永華近一步補充了區域海洋中心的發展願景以及人才梯隊建設方案,並介紹了區域海洋研究中心以及智慧城市物聯網國家重點實驗室的發展定位和目標。郭虔副局長介紹了澳門海事及水務局成立至今的歷史及發展,也對目前澳門大學區域海洋中心的發展表達了贊許和期待,並對進一步推動澳門水務與海事相關的科技專案,大力推動澳門海洋經濟表達了共同合作的意願。雙方一致表示,澳門大學與澳門海事及水務局應進一步增進交流,開展深層次的合作,共同開展澳門海洋產業經濟與災害防治的研究,共同推動澳門相關領域的進步與發展。